|

Brian Sims

Editor |

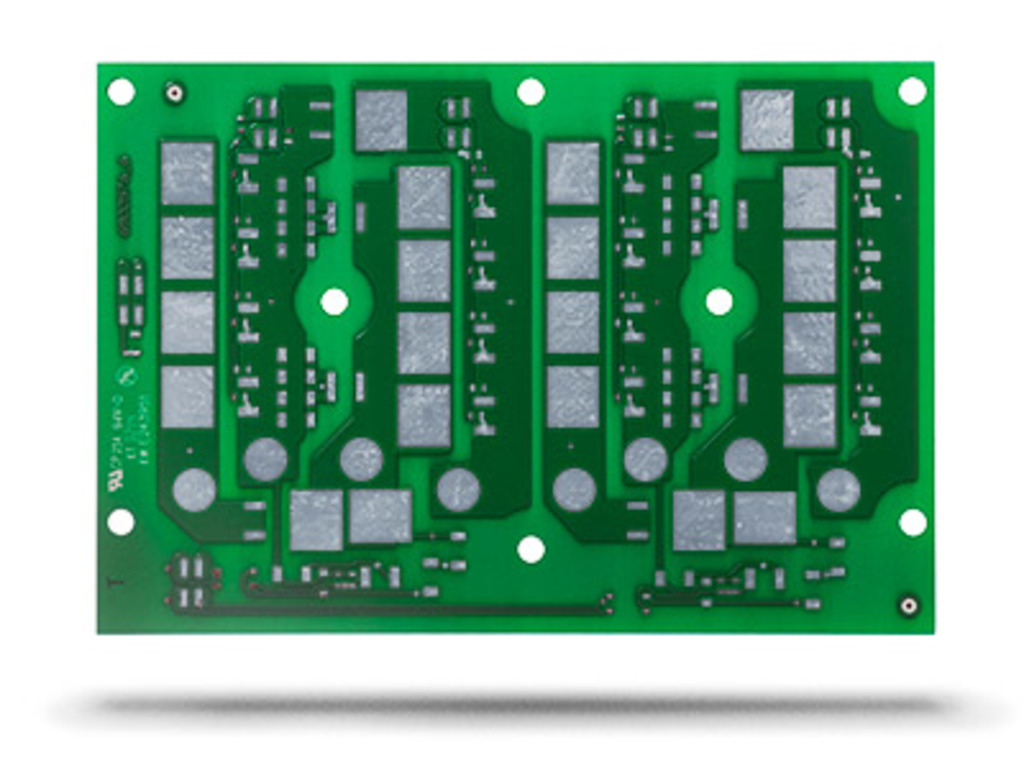

IMS – Insulated Metal Base PCBs

13 April 2022

NCAB has approved factories that are specialists in this field, with plants dedicated to IMS – Insulated Metal Base PCBs. This segment is growing rapidly and supporting sectors including automotive, medical, aerospace, lightning applications and industrial controls.

New opportunities with insulated metal substrate

For greater amounts of energy or local thermal loads, e.g in modern constructions with high intensity LEDS, IMS technology can be used. The abbreviation, IMS, stands for “Insulated Metal Substrate.” This is a PCB built on a metal plate – normally aluminium – on which a special prepreg is applied, the primary qualities of which are an excellent capacity for heat dissipation and great dielectric strength against high voltages.

The advantages of IMS PCBs for heat dissipation

An IMS PCB can be designed with a very low thermal resistance. If, for example, you compare a 1.60 mm FR4 PCB to an IMS PCB with a 0.15 mm thermal prepreg, you may well find the thermal resistance is more than 100 times that of the FR4 PCB. In standard FR4 products, it is very difficult to dissipate a large amount of heat away from components.

Read more about our material recommendations for IMS and other PCBs.

We also host seminars about IMS – Thermal management, how to calculate and design IMS boards. What alternatives are there to IMS boards?

You can always contact your local NCAB Group company if you need further information or assistance, we are happy to help you.

| Feature | NCAB´s technical specification |

| Number of layers | 1 – 4 layers |

| Technology highlights | Effective heat sink solutions for thermal applications. This construction type enables superior heat dissipation through use of either aluminium or copper substrate bonded to the insulated circuitry through thermal pre-preg or resin systems. |

| Materials | Aluminium & copper plates. FR-4, PTFE, thermal dielectrics. |

| Dielectric thickness | 0.05mm – 0.20mm |

| Thermal conductivity | 1-12 W/m/K |

| Profile method | Punching, Liquid cooled routing |

| Copper weights (finished) | 35μm – 140μm |

| Minimum track and gaps | 0.10mm / 0.10mm |

| Metal core thickness | 0.40mm – 3.20mm |

| Maxmimum dimensions | 550mm x 700mm |

| Surface finishes available | HASL, LF HASL, OSP, ENIG, Imersion tin, Immsersion silver |

| Minimum mechanical drill | 0.30mm |

- No related articles listed